大余县龙鑫光电制品厂 >

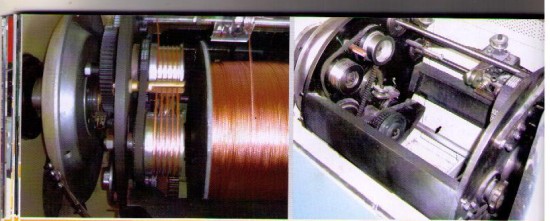

产品 > P型自动高速绞线机

| P型自动高速绞线机P Double twist bunching machine | ||||

| 特点:集国内外最新机型的优点设计制造。转速高,主轴为稀油润滑,自然冷却,油位自动报警,可降低机器的温度和噪音,延长机器无故障使用时间。过线系统为弓带直接到主轴导轮,减少绞线的刮伤,跳股等现象。使用磁粉离合器自动跟踪控制收线张力,使收线的张力从线盘底部到最大外圆是均匀一致。 | ||||

| Main feature:High rotate speed,main shaft is lubricate by thin oil,cool naturally, auto warning if oil not encough ,which can low temperature and noise of the machine ,extend the serivce life of the machine.Overline system is bow belt directly to idler pulley of main shaft ,which can scratch and cross section of stranded wire.Use magnetic powerder clutch auto track and control taking up tension of taking up even and consistent from the botton of wire carrier to the Max outer circle. | ||||

| 绞线机技术参数Double Twisting Bunching Machine | ||||

| 产品型号Machine type | 300P | 500P | 500P/B | 650P |

| 用途Machine usse | 用于7根以上裸铜线,镀锡线,漆包线绞合for bunching bare copper tinned wire enamelled wire (7wires one time at least | |||

| 控制方式Control type | PLC+触摸屏+变频控制PLC+HMI+Invertor Control | |||

| 绞合截面积Bunching section area(mm2) | 0.035-0.45 | 0.05-2.5 | 0.05-4.00 | 0.18-6.00 |

| 入线单丝直径Single wire size(mm) | ф0.05-0.25 | ф0.10-ф0.45 | ф0.10-ф0.52 | ф0.18-ф1.00 |

| 绞距(变换牵引轮更换绞距)Pitch(mm) | 3.65-17.15 | 6.3-50.4 | 6.3-65.0 | 11.61-66.03 |

| 绞向Bunching direction | 左右绞合均可S or Z | |||

| 收线张力控制Take-up type | 磁粉离合器自动控制张力tension controlled magnetic clutch | |||

| 最高土轴转速Max main shaft speed(rpm) | 3000 | 3000 | 2500 | 2000 |

| 排线方式Travsing type | 轴承式排线,排距,排幅可调Transverse and distance can be adjusted by bearing transverse | |||

| 轴承润滑方式Bearing lubrication | 稀油润滑,自然循环冷却thin oil lunbrication ,circulation coling | |||

| 收线盘上下盘方式Bobbin loading&unloading | 手动液压式Hydraulic type | |||

| 最大收线盘外径Max spol OD | ф300 | ф500 | ф500 | ф630 |

| 自动停机Auto-stop | 设定长度到达,内部,外部断线及其它故障时自动停车While reach setting length, inside outside wire break ,or other error auto-stop | |||

| 制动方式Break | 电磁刹车Magnetic break | |||

| 电机功率Motor Power(KW) | 4 | 5.5 | 5.5 | 7.5 |

| 主轴中心高度Main shaft center height(mm) | 630 | 700 | 700 | 850 |